OKMOS is inspired by the balance between the vivacity of the Hawk Moth, whose stability, speed and lightness guided the design of our e-board, and our industrial know-how, which guarantees reliability and quality.

The Hawk Moth represents all the essential characteristics of our unique riding experience.

Thanks to the founders’ professional experience, the idea was to develop a unique board that would be quick and easy to pick up for novice riders, while being very efficient for experienced riders.

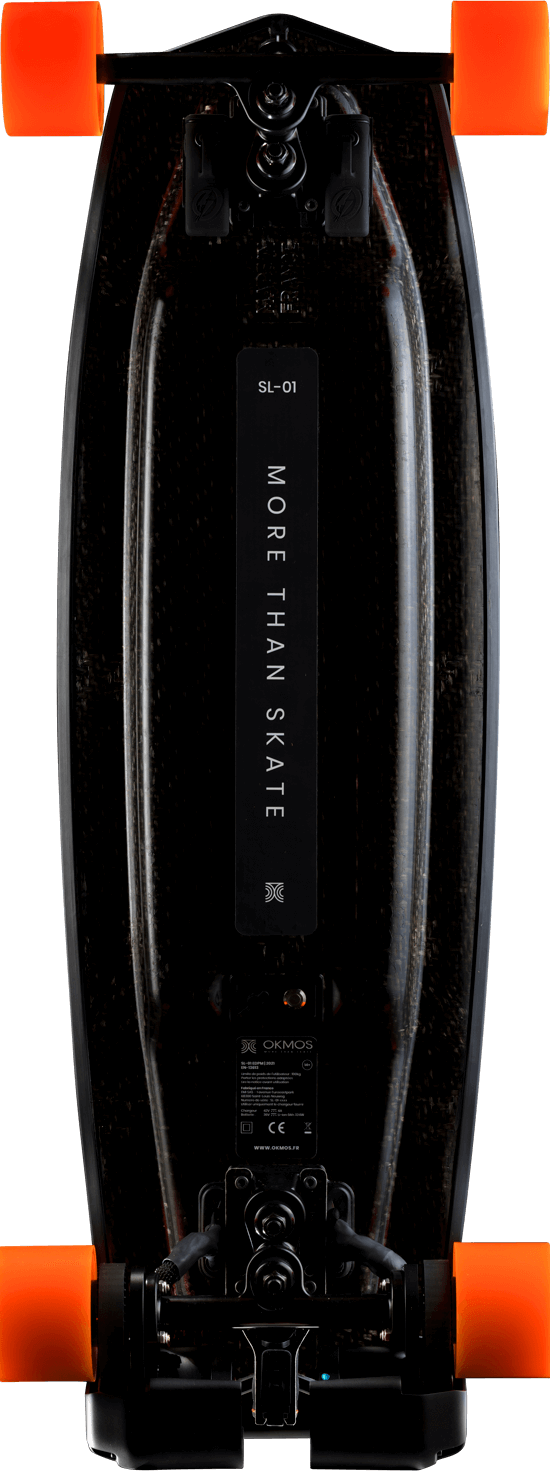

The industrialization of the production process of our e-boards allows us to provide a solid control of our know-how as well as a strong optimization of the costs. The one-piece deck, made of a polyamide matrix reinforced with glass fibers, is created in a single operation using Organosheet technology, an innovative technique used in the fabrication of sports cars.

Once assembled, each e-board is checked and tested on a test bench for final inspection before delivery.

The local economy is also favored by using partners from the area, and direct distribution is favored in order to eliminate intermediaries. The philosophy of the brand is not to get rich but to share sensations and experiences. All the e-boards are designed and produced in France and the investments come from exclusively French funds. Our brand is 100% owned by its founders.

The OKMOS community is a state of mind bringing together all types of riders around a feeling of freedom and conviviality. The goal of the riding experience is to share good times, no matter the level of experience, age or personality.

A cross between technology and performance, our French e-skateboards are made of Organosheet, a composite material composed of a polyamide matrix reinforced with glass fibers, making them more resistant than steel while being much lighter.

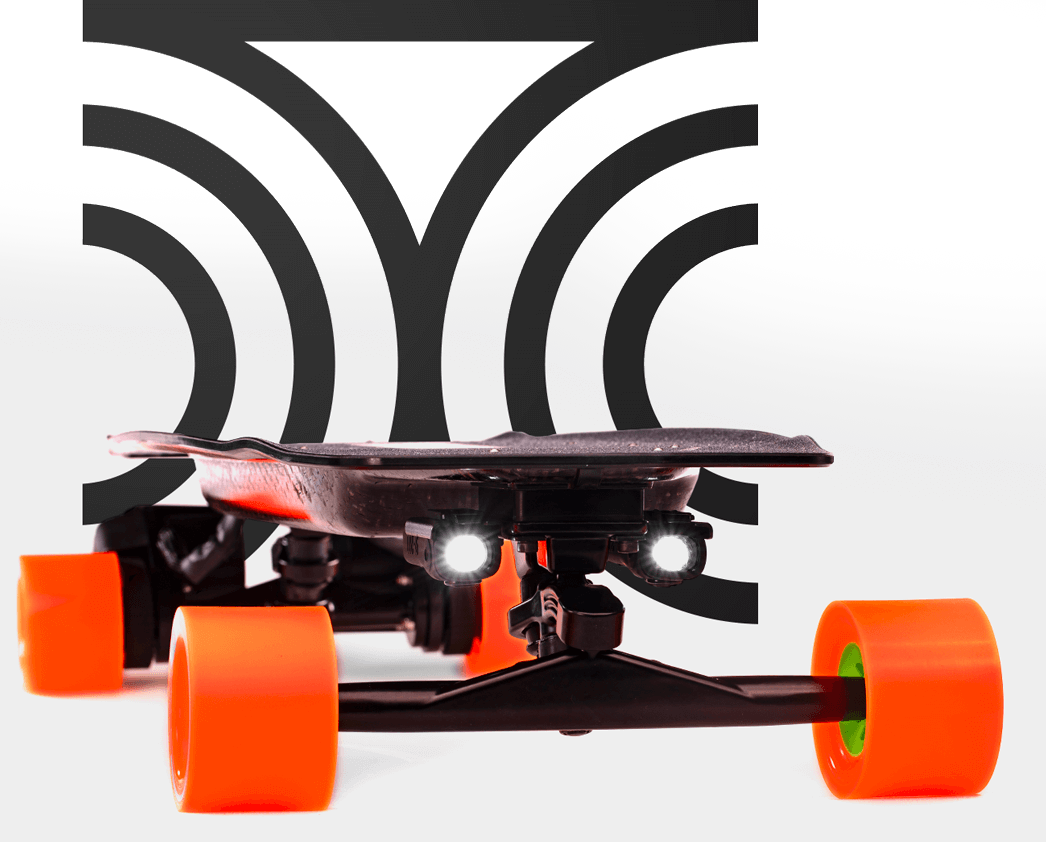

Thanks to its monobloc design, the deck integrates the electronic components directly into its box, protecting them from shocks and humidity.

Creation of the 3D design of the deck and the closure plate by our R&D department.

Execution of analyses, in particular rheological ones.

Fabrication of the hardened steel injection tool in our mechanical workshop.

Hybrid injection moulding process of the Organosheet plate on an injection molding machine with 700t closing strength.

Using a robot, the Organosheet plate is first heated in an infrared oven to 300°C and then put and held in the tool to be thermoformed and overmoulded in a single operation.

The truck fixing plate is first placed in the tooling by the robot in order to be overmoulded at the same time and in order to guarantee its retention in the middle of the board.

The mechanical and electronic components are integrated and assembled by our technicians.

Each e-board is then paired with its remote control.

The grip and stickers are applied individually thanks to application masks.

Traction tests, strength tests and waterproofing tests are carried out during the development phase of the product.

Before each shipment, the e-boards are checked on a test bench to guarantee their conformity and proper functioning.